Back

Back

Footwear testing methods [1/2]

In this blog post we would like to introduce to you the commonly used testing methods within the footwear industry. It should give footwear developer, designer, and engineers a guide on what tests to select and conduct when it comes to the selection of the right materials for footwear developments.

Why do I need material testing?

The testing of footwear components and materials is key to test the sufficient functionality of the later shoe even before the shoe is designed, sampled, produced or fit tested. By choosing the right material test, footwear developers and designers save time, money and energy.

Depending on the purpose a material must fulfil on the shoe, the material requirements can be quite different. In the right choice of tests, it plays a major role in whether the component has a design function, whether the part is visible or hidden, whether the part must fulfil a safety-relevant aspect or whether the part must have a certain performance. Each sport or footwear category has its own guidelines, standard tests or benchmarks.

In general, one can say that material tests ensure the design intent, the function, the safety, manufacturability and longevity (and thus also the sustainability) of a shoe.

Important definitions in material testing

Condition a material

Taking a material from its original form to a state of how it can be used in production.

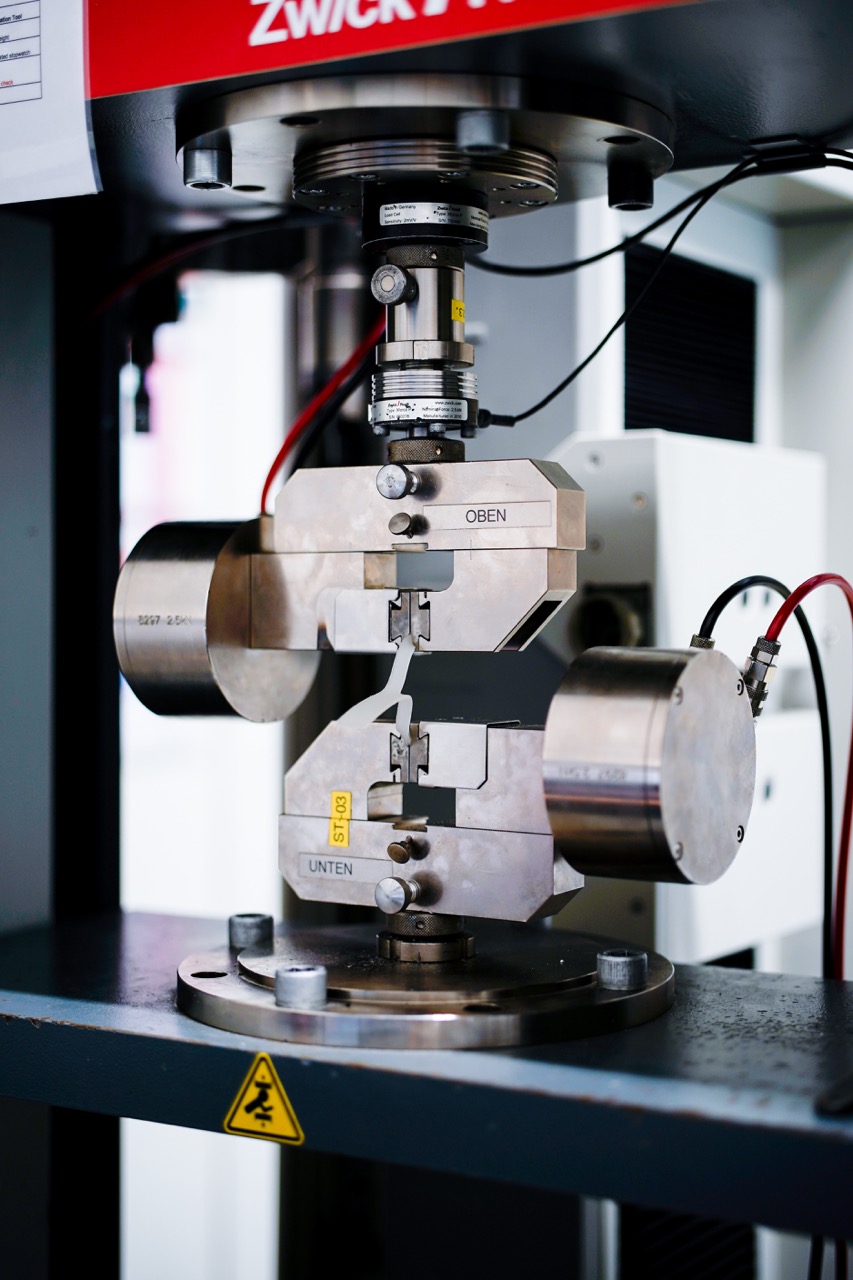

Tensile tester machine

Though the name of the machine is a specific test, this machine is used for the majority of tests as it can function with different speeds and distances. For each test, it is altered and put into the start position to start the tests.

Elastic material properties

Elastically means that the material will return to its original dimensions after deforming.

Plastic material properties

Plastically means the deformation of the material. Some fractions remain permanently and non-reversible.

Yield point

The limit between elastic behavior and the beginning of plastic behavior is called yield point (or yield strength). In brittle materials the ultimate tensile strength is close to the yield point, whereas in ductile materials the tensile strength can be higher. Polymers used in footwear applications belong usually to more ductile materials.

Test Specimen

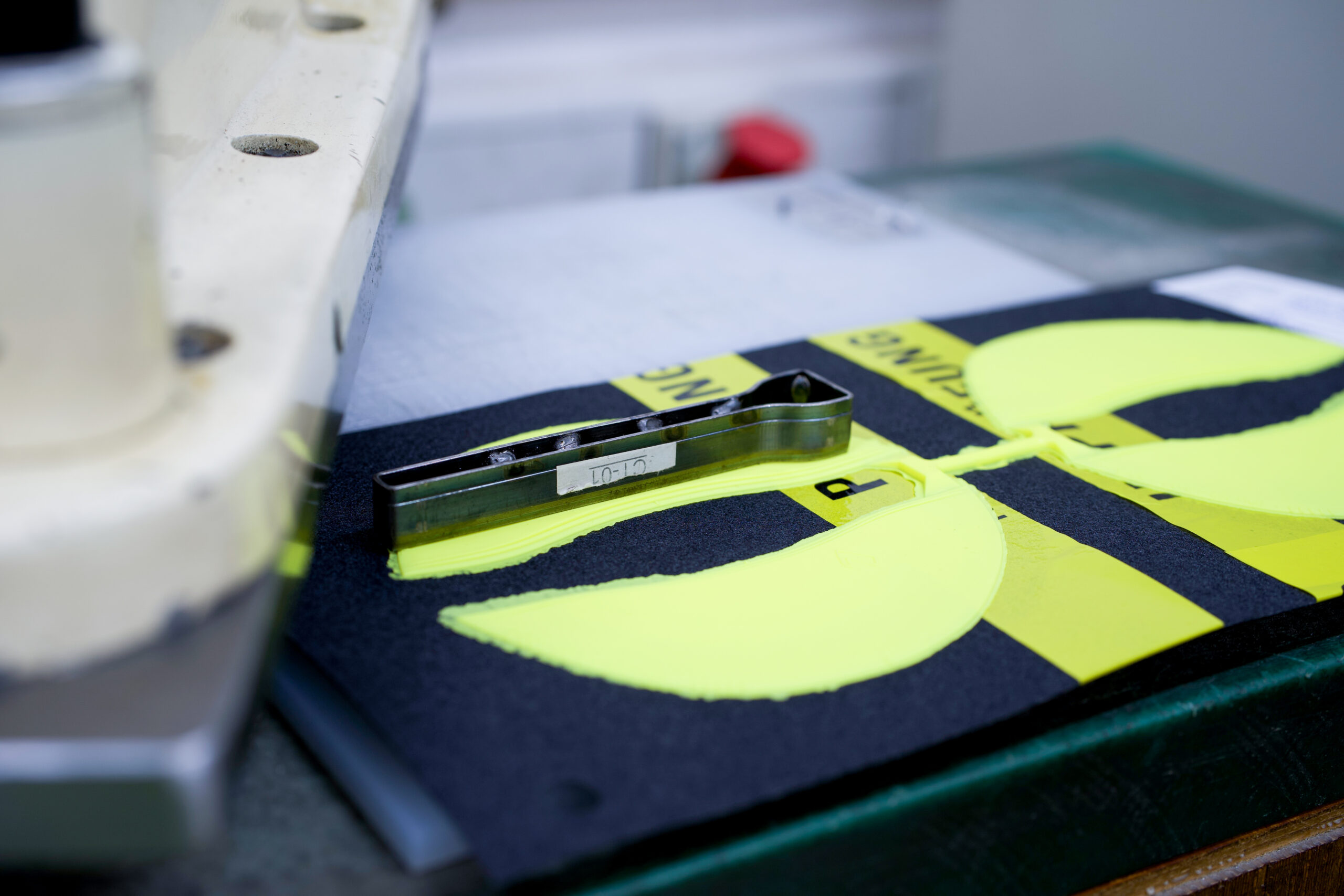

A test specimen is the material injected into a standardized shape/form to ensure that the test is comparable and can be conducted

Material tests done in the footwear industry

Mechanical tests

Mechanical properties concern mostly performance requirements. These tests focus on how the material is built, what it can endure in different aspects such as stretch, humidity, and abrasion. The tests include shore hardness, tensile strength, breaking elongation, E-Modulus, tear strength, abrasion resistance, traction, fatigue bending, resilience, 3-point bending test, stud tip pulling, dome test, shrinkage, slip safety test, compression set and bonding.

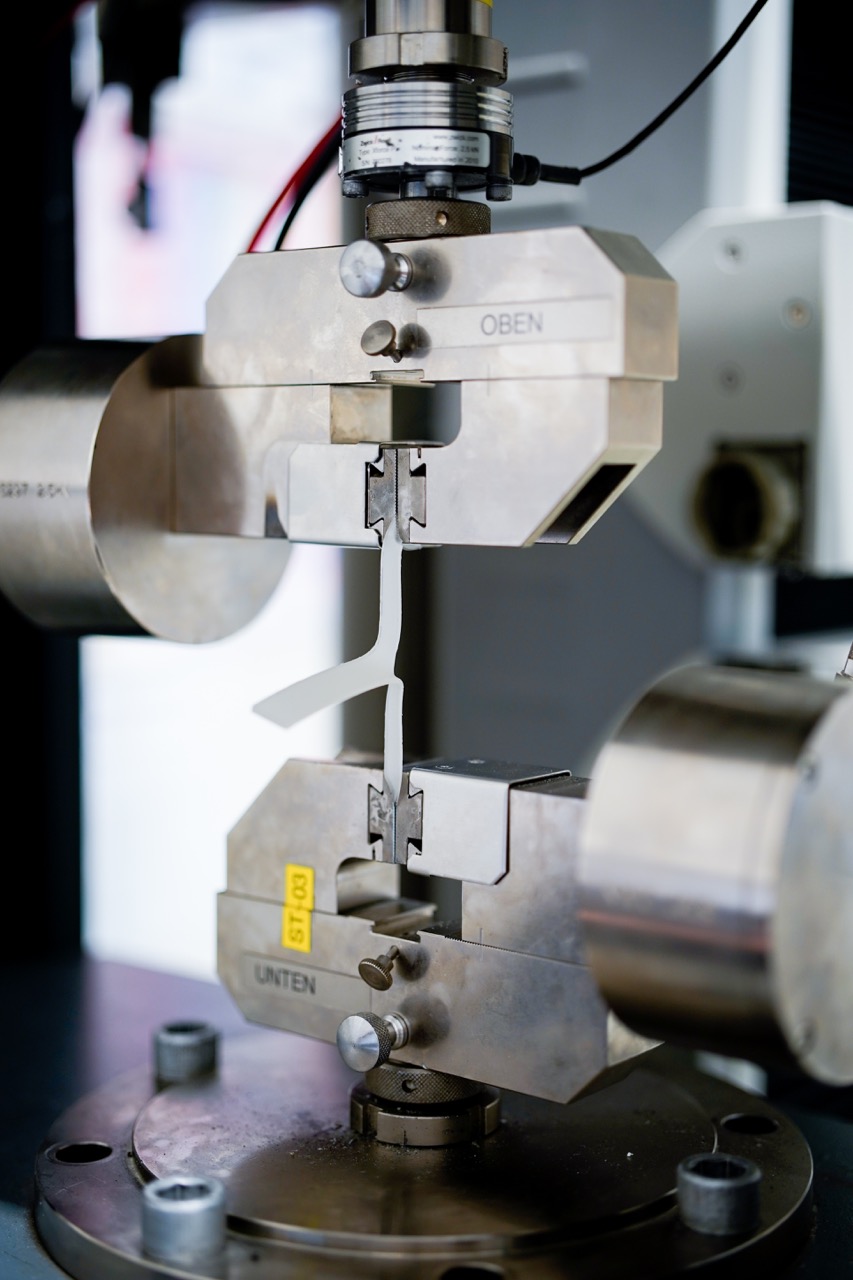

1. Tear strength

Purpose: Ripping materials in footwear can turn into serious function and safety issues. Moreover, ripping damages can reduce the lifetime of a shoe and are therefore sustainability issues. A material with a good tear strength ensures that the shoe does not rip when it gets stuck somewhere. The tear strength test determines the force at which a material with a cut or slit will begin to rip.

Setup and conditions: The machine used is a tensile testing machine. The test specimen has a length of 10cm, a width of 1.6cm and a thickness of 0.2cm. Each material type has its own way of being cut but the test is always conducted under normal room temperature conditions at around 23 degrees Celsius and at a relative humidity of around 50%. To start the test, the tensile machine must be set to the required test position which involves the right distance between the clamps and at the right velocity. Then, the load is set to zero and the test specimen with the pre-cut tear is placed between the clamps so that each shank of the test piece is held by the upper and the lower clamp. The test is then run at a predefined speed until the material totally breaks. Depending on the material, the tensile machine will stretch the material at different speeds.

What is measured: The measured value is the so called “moment of force” in Newton millimeters (N/mm). It tells us how much force was needed in the test to tear the test specimen 1 millimeter.

Interpretation of test result: The more force to tear a millimeter material is needed, the better the material will perform in your shoe. The required minimum value of the test to determine if the test passed or failed depends heavily on the application of the footwear and the individual footwear brands standards. You can say that usually footwear application should exceed a tear strength of 15 N/mm to succeed the tear strength test. The longer the test specimen takes to break, does not mean that the material is better. To compare two tested materials in their tear strength the same base force must be used.

Tested materials and components: The tear strength test is reasonable to conduct for a vast of materials. TPU and rubber outsoles are often tested.

2. Bonding test

Purpose: Each shoe consists of different materials which are glued or stitched together. In order to guarantee a good performance and a long endurance they must hold the shoe together. The bonding test is used to see how much force is needed to separate two materials or in other words how good a material bonds to another one. This is tested e.g. to check the bonding ability of an out- and midsole.

Setup and conditions: This test is done using a tensile strength testing machine. Four parts are tested per fabric for every size and color. The specimen is inserted into one clamp and the material into the other clamp. The machine is then started and observed until the two fabrics get separated. This test is similar to the tear strength test, the only difference is, that two materials are tested instead of one.

What is measured: Besides tensile strength and elongation of break, the bonding test takes especially the adhesion strength into consideration.

The adhesion strength (AS) [N/cm] is the relation of the recorded force and the width of the material specimen. It shows how much force is needed to initially start a detaching process of the bonding.

Interpretation of test result: Typical requirements for a footwear bonding are a minimum adhesion strength of 70 N/cm for polymers with a hardness >80 Shore A and 40 N/cm <80 Shore A.

Tested materials and components: There are several combinations of materials that could be tested: midsole with outsole, insole with midsole, inlining with toe caps and so on.

Purpose: The 3-point-bending test determines the maximum bending stress a footwear component can withstand and the tendency for a footwear component material to resist bending. In the footwear industry, it is often used to determine the bending functionality of especially fiber reinforced materials. For instance, Soccer or running outsoles need to have a certain bending flexibility whilst being exposed to highest exposed forces. Thus, the test can figure out footwear bending properties already at development stage.

Setup and conditions: The machine used is the Ross Flexing device. The first step is to bend the sole until squared edges are formed then draw a line cross the sole where the bends are. The sole is then put into the machine and the part with the bends gets flexed 250 000 times at 23 and -10 celsius to mimic the usage of the shoe. The deformation angle is 60 celsius.

What is measured: The amount of bend cycles a material can endure before breaking.

Interpretation of test result: If the sole did not break after 250,000 bend cycles, then it’s a success. The specimen is checked upon every 10-15 minutes to make sure it did not break in between.

Tested materials and components: The test is conducted on all fiber reinforced and composite materials, particularly on footwear categories with cleated outsoles.