Back

Back

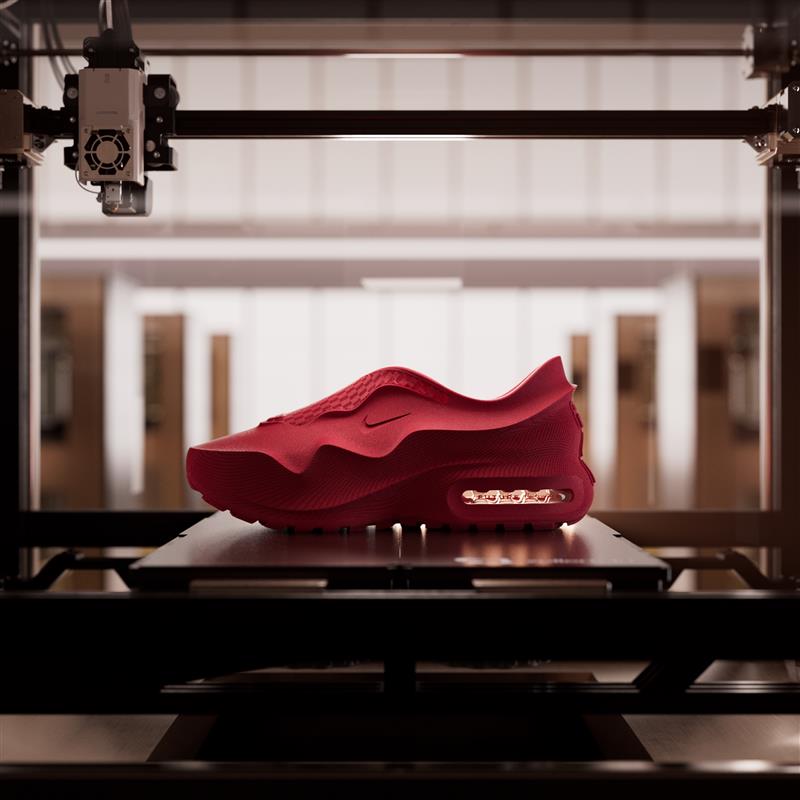

AI in Footwear Part I Long sentence topic test

In this week’s Sharepoint Post, René will explain to us the importance of 3D printing in the footwear industry.

Revolutionizing Footwear:

Additive Manufacturing (AM), commonly known as 3D printing, is transforming the footwear industry. By enabling innovative designs, reducing waste, and enhancing performance, AM is pushing boundaries and setting new standards. At framas, we are exploring these technologies to help our partners deliver the future of footwear.

Additive Manufacturing allows us to create complex geometries and tailor products to meet specific needs. However, in our work, it’s also a key to improving our process of mold making, by empowering traditional CNC Manufacturing with Additive Manufacturing.

Using cutting-edge materials and technology, brands can design and produce components and full shoes with unprecedented precision and functionality.

adidas has pioneered the use of 3D-printed midsoles with their Futurecraft 4D series. These midsoles are crafted using Digital Light Synthesis (DLS) from Carbon, which uses liquid curable resin to enable lattice structures that deliver precise cushioning and energy return.

On the other side, PUMA is pushing creative boundaries with its AM collaborations. The Mostro concept, featuring bold, lightweight lattice patterns, showcases how AM is not just functional but also aesthetically groundbreaking. This is a collaboration with the music artist A$AP Rocky.