framaprene is our sustainable heel counter compound made from 100% recycled materials. Developed to support circularity without compromising on performance, framaprene offers a sustainable solution for footwear brands aiming to reduce their environmental footprint while maintaining the quality of their products.

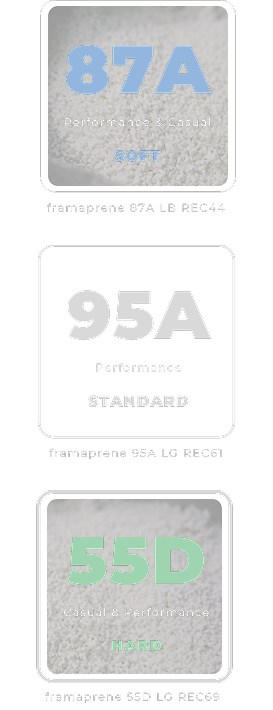

STANDARD GRADES

CUSTOMIZABLE

Hardness range of Shore 85A to Shore 70D

framaprene processing

We source high-quality recycled raw materials derived from post-industrial waste and compound them using our proprietary formulations to create framaprene – our 100% recycled heel counter compound. This material is then seamlessly integrated into our production process to manufacture durable, high-performance heel counters, supporting a circular and sustainable value chain from raw material to finished product.

High Impact PolyStyrene

Hard Component

Reprocessed post-consumer & post-industrial waste (consumer electronics & food packaging) from constant sources in Japan.

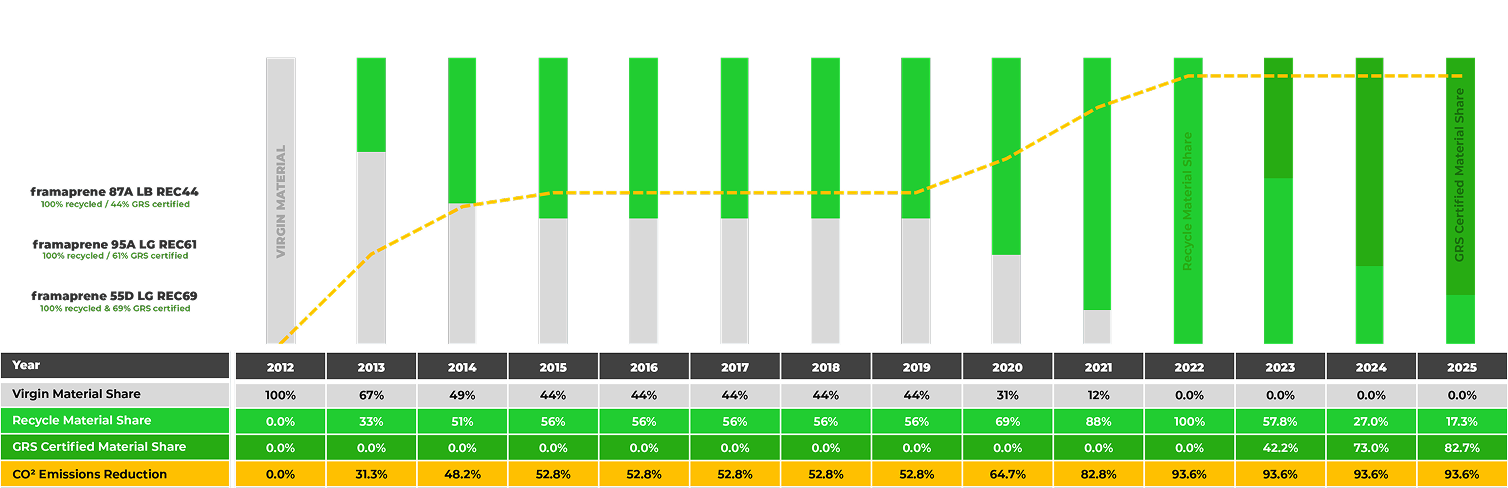

Since the replacement of the virgin Polystyrene share in framaprene heel counter compounds in 2012 more than 14,000 tons of recycled HIPS have been processed up to now.

Thermoplastic Elastomer

Soft Component

Reprocessed single-source post-industrial waste from the sanitary products industry (foil extrusion).

This source guarantees stable mechanical properties comparable to virgin TPE grades and enables our fully sustainable compounds to be used also for performance applications. Since 2020, framas used more than 4,000 tones of recycled R-TPE.

SUSTAINABLE MATERIAL DEVELOPMENT

framaprene Grades

Since 2012, we’ve steadily advanced the development of framaprene by systematically reducing the share of virgin material in our formulation. Each year, we’ve taken measurable steps toward full circularity, ultimately reaching a zero-percent virgin material ratio. Alongside this material transition, we’ve also significantly reduced CO₂ emissions year over year, reinforcing our commitment to sustainable innovation and responsible manufacturing.